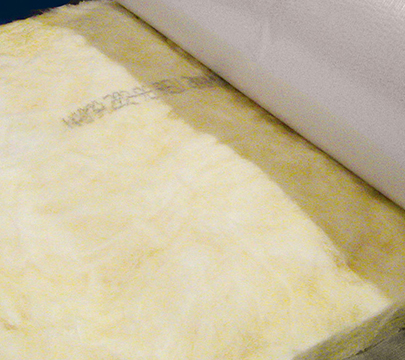

Faced Fiberglass

Bay Insulation Systems’ Faced Metal Building Insulation (MBI) is comprised of a resilient, light density fiberglass blanket (NAIMA 202-96® Insulation Only), laminated to a high quality vapor retarder facing, and is compliant with the NIA Certified Faced Insulation® 404.01-2022 Standard. Bay also offers Factory Mutual Approved Faced MBI.

Custom Lamination and Packaging

Every order is custom laminated to fit your building dimensions and criteria. Each roll is individually tagged to identify its intended location in the building roof, sidewalls and endwalls.

| R-VALUE | APPROXIMATE THICKNESS | AVAILABLE WIDTHS | LENGTH |

|---|---|---|---|

| R-10 | 3.0″ | 36″ 48″, 60″, 72″ | Custom laminated to length. |

| R-11 | 3.5″ | 36″ 48″, 60″, 72″ | Custom laminated to length. |

| R-13 | 4.0″ | 36″ 48″, 60″, 72″ | Custom laminated to length. |

| R-16 | 5.0″ | 36″ 48″, 72″ | Custom laminated to length. |

| R-19 | 6.0″ | 36″ 48″, 60″, 72″ | Custom laminated to length. |

| R-25 | 8.0″ | 48″, 60″, 72″ | Custom laminated to length. |

| R-30 | 9.5″ | 48″, 60″, 72″ | Custom laminated to length. |

Tab Options

Facing tabs are provided for sealing side joints between adjoining rolls of faced fiberglass. Bay Insulation offers several options:

| TAB METHOD | DESCRIPTION |

|---|---|

| Double 3″ Staple Tabs | Facing tabs from 2 adjoining rolls are pulled together between fiberglass joint and stapled with a long-nosed staple pliers. |

| Single 6″ No-Staple Tab | First roll of insulation is installed with 6″ tab as leading edge. Next roll is nested over tab from first roll. |

| Single 6″ “Reinforced” No-Staple Tab | Mylar reinforcement is added at 6″ tab to provide rigidity. |

| Single 6″ Self-Adhering No-Staple Tab | An adhesive strip with removable backer is added to 6″ tab for adhering tab to adjoining roll. |

| Double 12″ or 15″ Tabs | For use with double fiberglass layer “High R-Value” systems. Tabs from adjoining purlin spaces are lapped together over purlin. |

| Tuck Tab | For use in single layer application where a single 6″ tab is folded under the facing of the adjacent roll. |